Enhancing Quality Assurance with AOI Machines by Maker-ray

In today’s fast-paced manufacturing industry, ensuring product quality is of utmost importance. To streamline quality assurance processes, many companies are turning to automated solutions such as Automated Optical Inspection (AOI) machines. In this article, we will explore the benefits of AOI machines and shed light on how Maker-ray, a leading brand in the field, is revolutionizing quality control.

The Role of AOI Machines in Quality Assurance

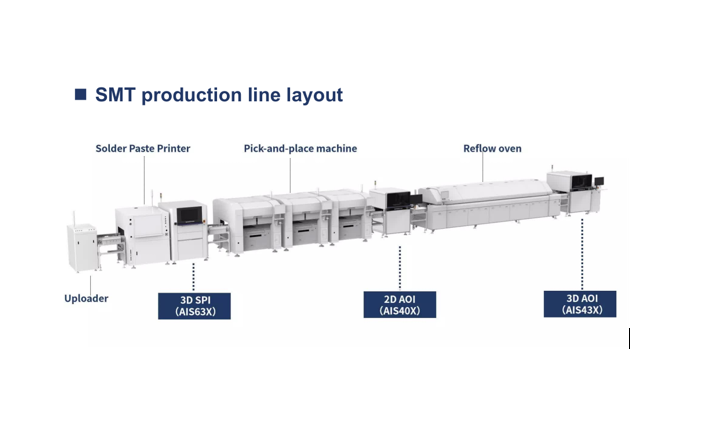

AOI machines play a vital role in detecting defects and anomalies in manufactured products. By utilizing advanced imaging technology, these machines can quickly and accurately identify issues that may not be noticeable to the human eye. Incorporating AOI machines into quality assurance processes helps eliminate errors, reduce rework, and maintain high product standards.

Key Features of Maker-ray AOI Machines

Maker-ray has gained recognition for its cutting-edge AOI machines designed to meet the specific needs of modern manufacturing. Let’s take a closer look at some standout features:

Advanced Imaging Technology: Maker-ray AOI machines employ state-of-the-art imaging algorithms to capture highly detailed images of products at lightning-fast speeds. This enables efficient detection of even the smallest defects, enhancing overall inspection accuracy.

Intuitive User Interface: With an intuitive user interface, Maker-ray AOI machines make it easy for operators to navigate through various inspection settings and parameters. The user-friendly controls allow for quick setup and seamless integration into existing production lines.

Customizable Inspection Criteria: Maker-ray understands that different industries have unique quality requirements. Their AOI machines offer flexibility in defining inspection criteria, allowing manufacturers to tailor the inspection process to their specific needs. This adaptability ensures precise defect detection without unnecessary false positives.

Achieving Optimal Results with Maker-ray AOI Machines To maximize the effectiveness of AOI machines from Maker-ray, consider the following best practices:

Optimal Placement: Properly positioning AOI machines in the production line is crucial. By strategically placing them at critical checkpoints, manufacturers can identify defects early on, preventing costly downstream issues.

Regular Calibration: Periodic calibration of AOI machines ensures accurate and consistent results. Maker-ray provides comprehensive calibration guidelines to maintain optimal performance and guarantee reliable defect detection.

Conclusion

In today’s competitive manufacturing landscape, maintaining impeccable product quality is non-negotiable. AOI machines have emerged as a valuable tool to achieve this goal effectively. Maker-ray’s innovative AOI machines offer unparalleled accuracy, flexibility, and usability, making them an ideal choice for businesses seeking to enhance their quality assurance processes. By embracing AOI technology and leveraging the expertise of Maker-ray, manufacturers can elevate their quality control standards and stay ahead of the curve.